The BOTS are coming, and before jumping into your Tesla or grandma's house, they are taking a peek at restaurants and warehouses.

Today, we are looking into Flippy designed and installed by Miso Robotics. Crafted to seamlessly integrate into existing kitchen spaces, Flippy is a sophisticated robotic solution designed for the modern culinary [restaurant] environment.

Its design allows it to be positioned over the standard fryers and holding areas, requiring no modifications to the established infrastructure of a restaurant. With a versatile frame that caters to varying numbers of fryers, Flippy brings together a robotic arm and a mobile rail system to navigate the frying station efficiently.

The additional attachments, such as auto bins and specialty baskets, are adaptable and can be placed on either side to complement the kitchen’s existing workflow, catering to a wide array of frying needs, from regular fries to more delicate items like onion rings.

To ensure utmost safety, a fryer safety barrier is integrated to protect staff from potential hazards such as hot oil.

Flippy is operated with a simple tap, triggering the dispensing and cooking of high-demand items while its advanced AI-powered cameras identify and monitor a variety of foods.

Post-cooking, Flippy ensures that food is correctly placed into the holding area and ready for the final touches and packaging. This system not only propels kitchen throughput and elevates data analytics but also minimizes the potential for overcooking, cross-contamination, food waste, employee injuries, and labor costs.

Key Takeaways

- Flippy integrates effortlessly with existing kitchen layouts and enhances food preparation processes.

- The innovative robot is equipped to handle a diverse range of food items, bolstering kitchen versatility and safety.

- Utilizing artificial intelligence, Flippy improves operational efficiency and food quality while minimizing various risks and costs.

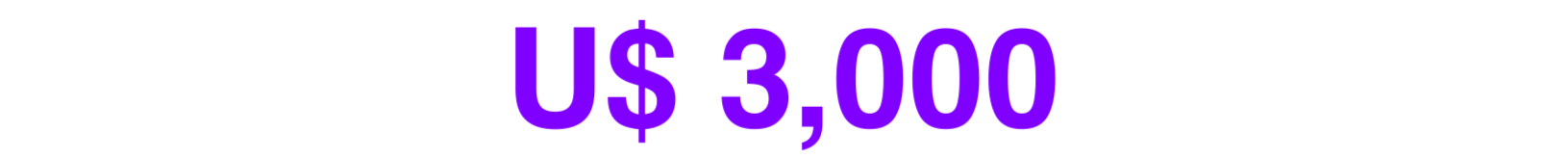

$$$

At this point, you may have the question: how much does it cost? Business owners can rent Flippy for just a little bit over:

Understanding Flippy

Flippy's Capabilities

It boasts a versatile structure to accommodate varying fryer counts and includes a maneuverable arm that traverses the frying area on a rail system. Single-touch activation allows staff to initiate food preparation from the holding unit, which caters to high-demand items such as classic fries and seasoned twists. Flippy introduces enhanced efficiency and data insights, mitigating concerns like overcooked items, contamination, waste, injuries, and inflated labor expenditures, making the kitchen environment more amiable and secure.

AI-powered vision systems promptly identify the food items, triggering Flippy to begin the cooking process. Once the food is cooked, it is relocated to the warming area, ready for the finishing touches and packaging. The amalgamation of these elements with intelligent software streamlines operations and fosters a more efficient and safer kitchen environment.

Flippy's Framework

Core Structure

The foundation of Flippy is designed to integrate seamlessly above the existing frying areas without necessitating any modifications to the current kitchen layout or operational procedures. This core structure has the versatility to adapt to a varying number of fryers, ensuring compatibility with different kitchen setups.

Mechanized Appendage and Mobility Track

The pivotal element of this system is the mechanized appendage, coupled with a mobility track that empowers the appendage to traverse along the fry cook station. Installing an automated receptacle and particularized basket assembly is flexible, accommodating either side of the central framework to align with each restaurant's simplified workflow.

- Cooking with Precision and Handling: The AI-equipped cameras instantaneously identify the type of food to be cooked, prompting the robotic mechanism to commence the frying process accurately. Upon completion, the system deposits the food into a warming station designed for final preparation and packaging.

- Operational Advantages:

- Enhances overall cooking efficiency and data gathering

- Diminishes the incidence of overcooking and cross-contamination

- Reduces wasted resources, employee injuries, and workforce expenses

- Impact on Work Environment:

- Culinary establishments become more welcoming, effortless to manage, and secure

- Assists in crafting an improved dining experience when incorporated into the frying workflow

The innovative system can be incorporated on either side of the central frame, tailored to align with each restaurant's operational flow. This setup includes automated containers and customized baskets designed to accommodate a variety of menu items that are not kept in the primary dispenser.

Utilizing these additions allows employees to handle diverse food products, including more delicate fare such as onion rings and stuffed tacos.

| Safety Feature | Employee Benefit |

|---|---|

| Fryer Safety Barrier | Protection from hot oil and potential spillage |

| Automated Cooking Process | Reduction in overcooking and contamination risks |

By integrating these systems, throughput is substantially increased, and data analytics are enhanced, beneficially impacting many facets of restaurant operations. From reducing waste to minimizing staff injuries and lowering labor expenses, the presence of this robotic companion makes restaurants more efficient, secure, and hospitable spaces for employees and patrons alike. For additional information, please visit misorobotics.com.

Intelligent Food Identification

Artificial intelligence is a cornerstone of the system, employing smart cameras that instantaneously identify different food types. As the camera detects food, the robotic arm is activated to commence the frying process. Upon completion, the system places the cooked items into a heated holding area. This is where food awaits final touches, such as seasoning and packaging. The inclusion of AI not only streamlines the cooking process but also bolsters data gathering, which can inform better operational decisions.

| AI Functions | Impact |

|---|---|

| Food Detection | Triggers precise cooking sequences |

| Movement to Holding Area | Prepares food for finishing steps |

| Data Collection & Optimization | Refines operations and outcomes |

Advantages in Protection and Performance

Ensuring Worker Protection

- Protective Barrier Installation: An implemented safety guard effectively shields staff from the dangers of hot, slick oil.

- Automated Precision: Utilizing a press of a button, employees can cook certain high-volume items, diminishing the risk of exposure to hot surfaces.

Enhancements in Operations

- No Disruption to Existing Spaces: The system seamlessly integrates over current kitchen setups without the need to alter the layout or daily procedures.

- Modular Framework Accommodation: A versatile frame caters to different fryer counts and can be equipped on either side to align with the kitchen's operational flow.

- Diverse Food Handling: Besides the high-volume food dispenser, additional bins and baskets are present to manage a vast range of foods, including delicate items like onion rings and tacos.

- Intelligent Automation: AI-powered cameras instantly identify food items, allowing precise and efficient cooking, followed by organized transfer to a holding area.

- Streamlined Process Efficiency: Integrating this technology boosts overall throughput, enhances data-driven insights, minimizes instances of overcooking and cross-contamination, reduces waste, and cuts down on both labor costs and the occurrence of employee injuries.

A couple of thoughts

There's undeniable value for the business owners as workers' availability and retention plague the industry. Not just because it's hard to find people but because a few want to be exposed to messy and hot environments for the type of work. And often with pay rates that are only enticing for a short time. Essentially, the ones that accept the job bolt away as soon they find something better/different.

The ethical issue will continue to shape, but the ginormous elephant in the room is that the few workers necessary for the final touch are paid the same as before. As the tech improves, even those will be replaced by automation. Fast food doesn't require the eye or mama's touch. Nonetheless, food that is cardboard quality (on a healthy scale, not what our brain perceives 🍔) is soon to be done by a cardbord-making machine. Food for thought?

That is all for today, now I really want a burger and a ton of fries!