When Google got too big and felt the need to build a holding that would contain all of its companies, they looked at the alphabet for the name! Others applied the Walt Whitman concept:

there were two roads in the digital woods and we picked the less beaten neural network path. And for that reason, we are different!

Well... maybe not exactly to the quote but hallucinations were an issue then as much in the era of AI now 🤖 👿 🤖

The landscape of logistics and warehousing is undergoing a significant transformation fueled by the integration of artificial intelligence and robotics.

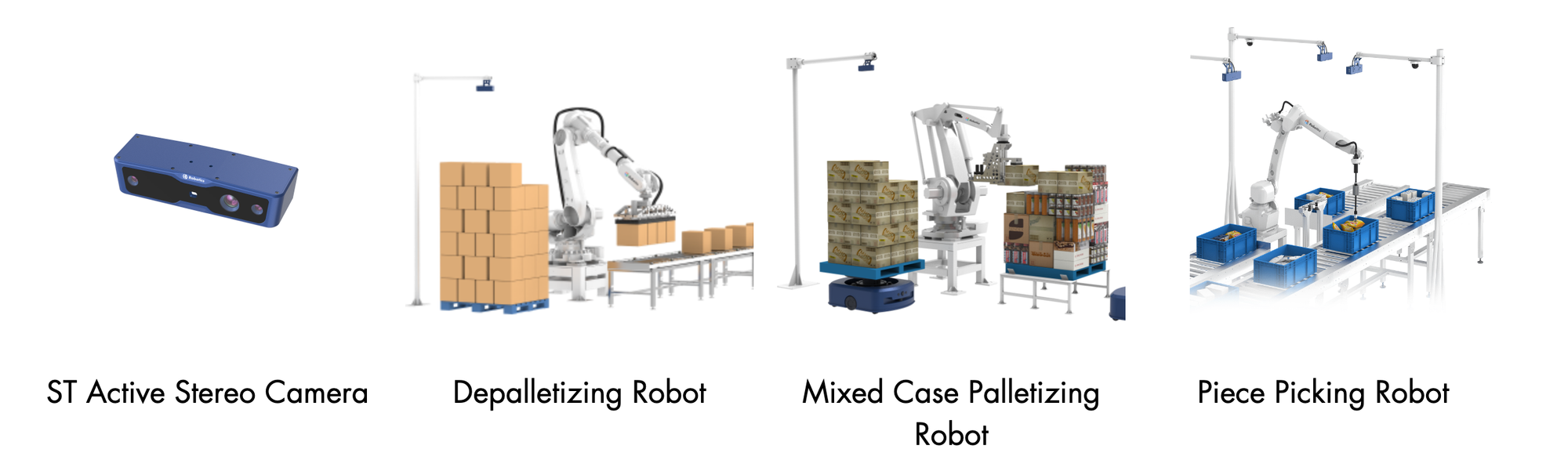

Among the [new] pioneers in this field, XYZ Robotics has established itself as a notable player, having secured substantial funding for its innovative solutions designed to reshape how warehouses operate. The company's robotic systems promise to streamline the picking process, a critical and time-intensive part of warehouse logistics, by deploying autonomous robots capable of handling a variety of tasks with precision and speed.

These technological advancements align with broader industry trends, as the warehouse robotics market is expected to burgeon, with projections pointing to a multi-billion dollar industry within the next several years. XYZ Robotics' solutions are at the forefront, aiming to enhance productivity and efficiency in logistics operations. By leveraging machine vision and cutting-edge robotic intelligence, their platforms are not just optimizing the picking process but also introducing new levels of safety and interactivity between machines and human workers in warehouse environments.

As robotics in warehousing moves from mere automation to true autonomy, concerns around safety and job displacement are also brought to the fore. Companies like XYZ Robotics are not just contributing to a more efficient supply chain but are also instrumental in setting the stage for how modern warehouses may navigate the delicate balance between human labor and robotic assistance. With a strong emphasis on both innovation and safety standards, XYZ Robotics' autonomous warehouse robots are indeed emblematic of the next generation in warehouse automation.

Evolution and Impact of Autonomous Warehouse Robotics

The autonomous warehouse robots developed by companies like XYZ Robotics mark a transformative progression in logistics and supply chain management. They signify major shifts in efficiency and operational dynamics within fulfillment centers.

Historical Development of Warehouse Robots

The journey of warehouse robotics began with the advent of simple automated machines designed to assist in the movement of goods. The game-changing moment in this history came with Kiva Systems, whose robots revolutionized the logistics industry. Acquired by Amazon and later renamed Amazon Robotics, Kiva's technology laid the foundation for today's sophisticated robots, like Proteus, which is Amazon’s latest fully autonomous warehouse robot capable of safely moving through the work environment alongside employees.

Market Growth and Startup Ecosystem

The market for autonomous warehouse robots has witnessed exponential growth. Numerous startups have emerged, fueled by significant investment from venture capitalists and industrial innovation funds. For instance, inVia Robotics has chronicled the evolution of this technology, highlighting the increasing capabilities. This surge signifies the technology's growing importance and the business world's strong belief in its potential to redefine fulfillment.

Impact on Employment and Workplace Dynamics

The introduction of warehouse robotics has been transformative for employment and workplace dynamics. There is a concern among workers that automation may replace jobs, leading to tensions within the human workforce. However, companies argue that robots like Proteus are designed to collaborate with people, creating safer and more efficient environments. This intersection of human and robot labor is, as covered by Forbes, a double-edged sword, spurring both efficiencies and safety concerns. The ongoing trend points toward a need for workers to adapt to new roles that technology inevitably brings.

Technical Advancements in Warehouse Robotics

Recent years have witnessed significant progress in the capabilities of warehouse robots, primarily driven by advancements in artificial intelligence, machine learning, and robotic engineering. These developments are enhancing the efficiency, accuracy, and safety of supply chain operations.

Perhaps the one that has hit the headlines quite bit in the 4th quarter of 2023 is Stretch by Boston Dynamics. Grabs boxes and moves them over a convey belt to help human to save their back!

Breakthroughs in Robot Mobility and Perception

The mobility of warehouse robots has seen transformative improvements, particularly in autonomous mobile robots (AMRs). These robots utilize advanced navigation technology to maneuver around warehouses with increased speed and precision. Research and development efforts have led to more sophisticated algorithms that allow for dynamic path planning, which helps in adapting to changing warehouse environments in real-time. Additionally, robots have become more perceptive, with sensors that can accurately detect and interpret their surroundings, leading to safer and more proactive operations.

Innovations in Computer Vision and Machine Learning

The integration of deep learning into computer vision systems is a game-changer for warehouse robotics. Modern robots are equipped with advanced vision systems that enable them to recognize an array of objects, even under varied lighting and positioning. This is a result of machine learning models that have been trained on vast datasets, allowing robots to not only see but also understand their environment to make informed decisions during tasks such as sorting and inventory management.

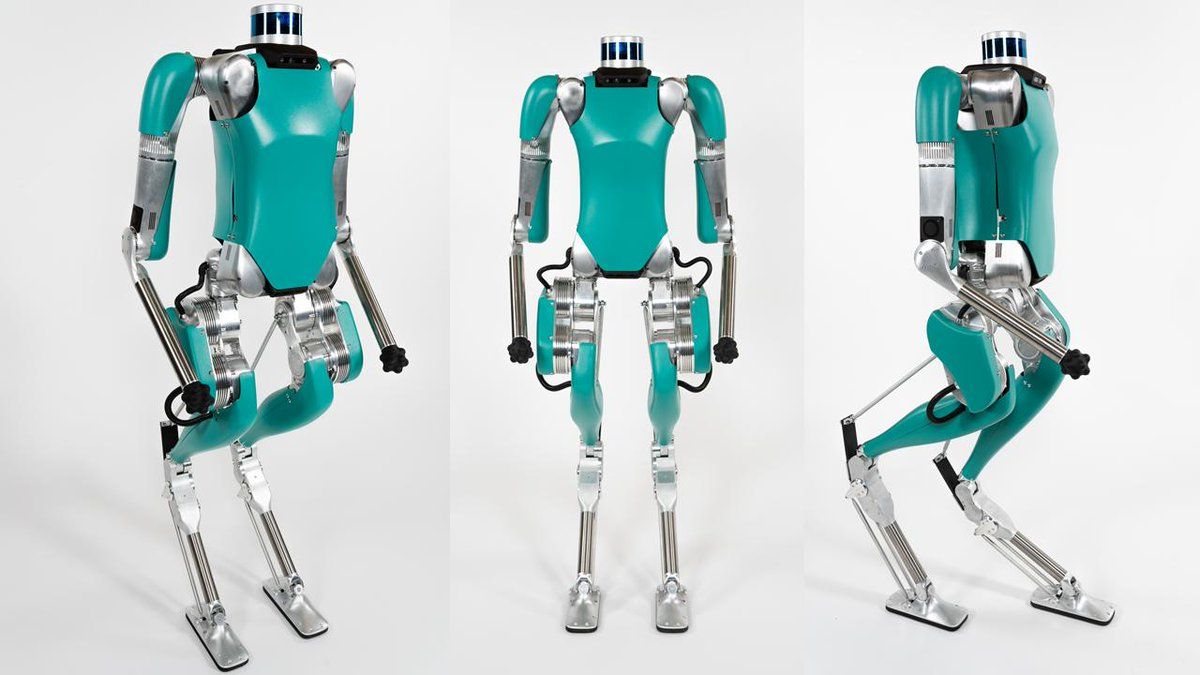

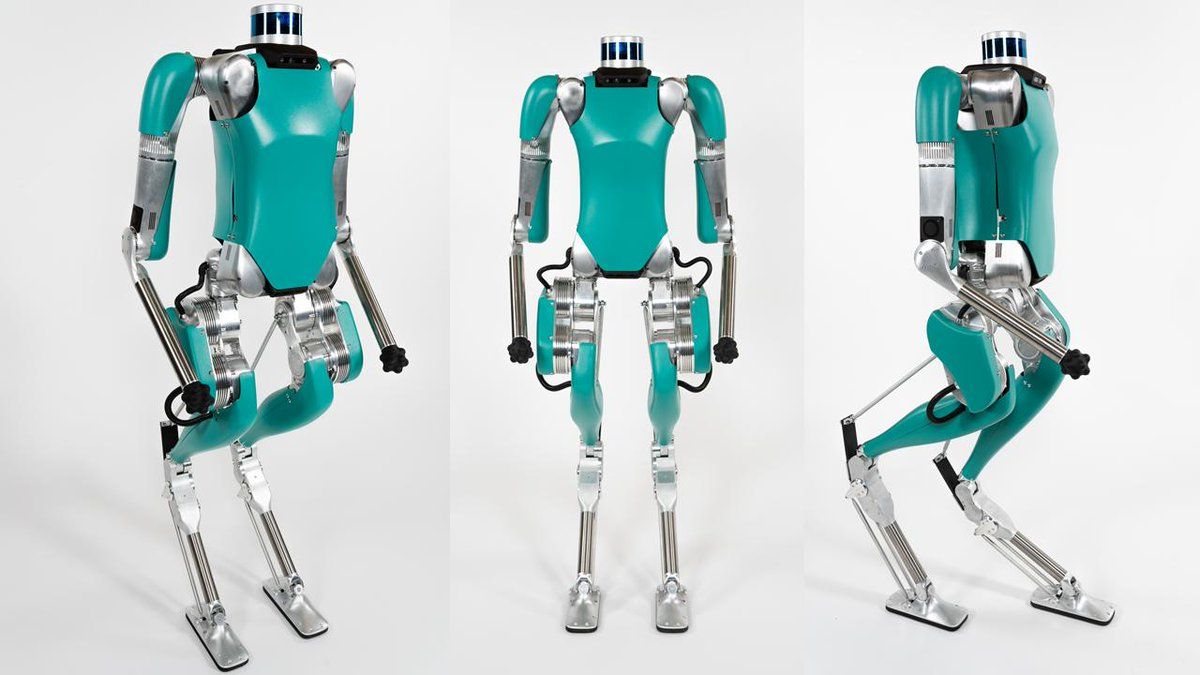

A great example of this type of technology at work and in the context of warehousing is DIGIT by Agility Robotics.

Enhancements in Picking and Packing Technology

At the forefront of warehouse automation are robots designed specifically for picking and packing tasks. Technological enhancements have led to the development of more dexterous robotic arms with sophisticated grasping mechanisms. These allow for handling a diverse range of products with care and precision. The utilization of artificial intelligence has optimized the way these robotic systems approach picking strategies, further increasing throughput and decreasing the likelihood of product damage or errors during the picking process.

Operational Integration of Autonomous Robots

XYZ Robotics is revolutionizing the landscape of warehouse operations through the strategic integration of autonomous robots. These robotic systems are designed to enhance efficiency, increase productivity, and ensure high safety standards while working alongside human workers. And they aim to accomplish all that through workflow optimization and safety in navigation, not just to humans but also to things. And things matter... given the size of shelving in warehouses.

Workflow Optimization with Robots

The deployment of autonomous robots within warehouse systems dramatically optimizes workflow processes. Autonomous robots are adept at sorting, picking, and transporting containers with precision. Their efficiency in repetitive tasks allows for a smoother logistics flow and raises productivity levels. By offloading these routine tasks to robots, human workers can focus on more complex issues that require critical thinking. And from the video above, you may understand why!

Safety and Human-Robot Collaboration

In XYZ Robotics' robotic systems, safety is paramount. Autonomous robots are equipped with sensors and machine learning algorithms that enable them to detect and navigate around obstacles, significantly reducing the risk of injury. Collaborative operations are carried out with a focus on human-robot interaction, where robots assist human workers, rather than replace them. This collaboration occurs both within and outside of designated caged areas to maintain a safe work environment.

Logistics and Supply Chain Synergies

Robotics are now pivotal in creating synergies across the supply chain and logistics networks. XYZ Robotics' autonomous robots streamline processes from inventory management to order fulfillment in fulfillment centers. Their integration into supply chain operations reduces the time it takes for products to move from storage to shipping and ultimately to the customer, thus improving the overall responsiveness of the supply chain.

Case Studies and Real-World Applications

As e-commerce and retail industries strive for efficiency, autonomous warehouse robots have become pivotal in optimizing fulfillment and shipping operations. Case studies of Amazon Robotics and Walmart highlight the practical benefits of these technologies.

Amazon Robotics and Kiva Systems

Amazon Robotics, formerly known as Kiva Systems, has pioneered the use of robots in their fulfillment centers. They incorporate thousands of mobile robots that maneuver across warehouses, systematically organizing and transporting goods. This automation results in accelerated order processing which is essential for Amazon's high-velocity e-commerce operations. The efficiency gained through this cutting-edge technology has set a benchmark for competitors in the retail sector.

Walmart’s Use of Robotic Drive Units

Walmart has implemented a fleet of robotic drive units to manage their vast inventory. These robots navigate through aisles to retrieve items, enabling faster fulfillment of online orders. Minimizing human intervention in the inventory retrieval process helps Walmart reduce errors and enhance shipping speeds, meeting consumer expectations for swift delivery. Walmart's adoption of robotic technology underscores the retail industry's shift towards more autonomous supply chain solutions.

The Future of Autonomous Warehouse Robotics

As the landscape of logistics and distribution continues to evolve, the future of autonomous warehouse robotics stands at the forefront of this transformation. This section underscores how trends will shape robotics evolution, identifies potential challenges and opportunities, and explores the importance of strategic investment in this technology.

Trends Shaping the Future of Robotics

Current trends suggest that the autonomous mobile robot (AMR) technology will keep advancing, focusing on efficiency and accuracy. Robots in warehouses are becoming more adept at navigating complex environments. This is driven in part by the Covid-19 pandemic which has accelerated the shift towards robotics because of needs stemming from supply chain disruptions. The use of robotics technology has been vital in maintaining productivity during periods of workforce shortage.

There is a splitting philosophy on what kind of robotics paths we will be developing over time. A trend says we need massive arm robots like the ones the Boston Dynamics Stretch and XYZ are leading on and another stronger trend that claims "the environment is designed for humans." therefore, we need a humanoid form of robots because they will adapt to the environment and requires less ad-hoc changes to the spaces where they operate. Like Digit.

Challenges and Opportunities Ahead

The journey of implementing autonomous robots is not without its obstacles. Safety concerns are paramount as these machines must integrate seamlessly with human workers without incidents. Moreover, these systems require significant investment and possess a learning curve that must be addressed through training and adaptation. However, these challenges present opportunities for innovation, particularly in achieving a high return on investment by reducing long-term costs and increasing output.

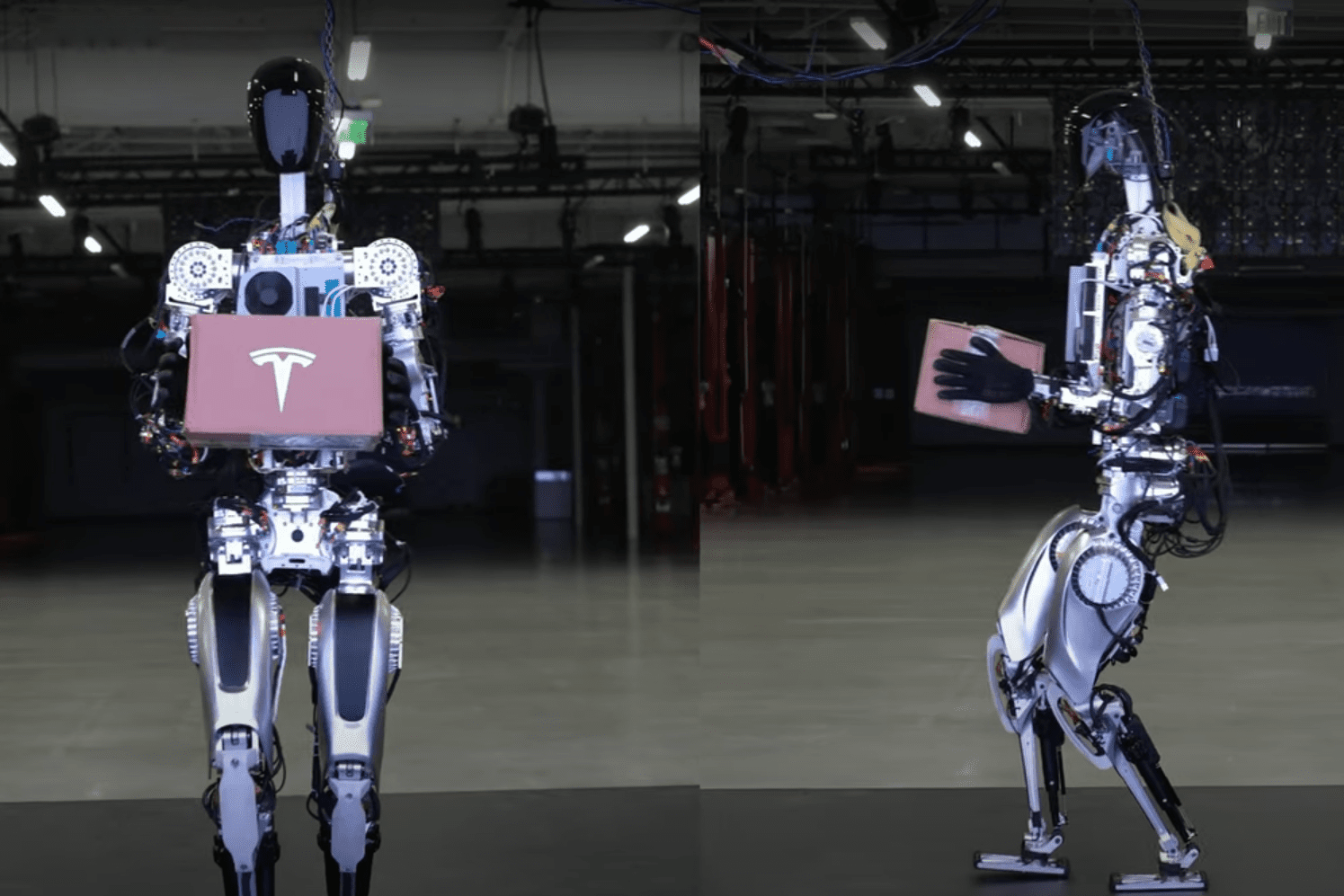

The Goliah in disguise when it comes to full autonomy is Tesla

Investing in Robotics and Long-Term Vision

Leaders, including CEOs, are recognizing the long-term benefits of investing in autonomous warehouse robotics. A long-term vision focuses on scaling operations sustainably and meeting the ever-growing consumer demands. The investment in robotics is expected to lead to continued improvements in speed, accuracy, and efficiency.

Frequently Asked Questions

The topics covered in this section address common inquiries about the functionalities, technologies, integration capabilities, safety features, recent financial impacts, and competitive distinctions pertaining to the autonomous warehouse robots developed by XYZ Robotics.

How do XYZ Robotics' autonomous warehouse robots enhance operational efficiency?

XYZ Robotics' warehouse robots are configured to streamline warehouse operations by automating the process of picking, sorting, and moving inventory, consequently reducing the time taken for these tasks and minimizing human error.

What technologies do warehouse robots by XYZ Robotics incorporate for navigation and task completion?

The autonomous robots from XYZ Robotics employ sophisticated AI-enabled robotic perception and manipulation technology, which allows them to navigate efficiently and handle a variety of materials with precision.

Can XYZ Robotics' automated robots integrate with existing warehouse management systems?

Yes, the robots designed by XYZ Robotics are built to seamlessly integrate with current warehouse management systems, enhancing their ability to communicate and collaborate within existing logistical frameworks.

What safety features are included in XYZ Robotics' warehouse automation solutions?

XYZ Robotics has incorporated multiple safety features into its robots, including sensors and software that enable the machines to detect and avoid obstacles, ensuring safe operation alongside human workers.

How has the recent funding affected the development of new warehouse robots by XYZ Robotics?

The recent Series A+ round of $17 million in funding has notably propelled the scaling up of research and development for XYZ Robotics, resulting in the advancement of their autonomous robotic solutions.

In what ways do XYZ Robotics' warehouse robots differ from those offered by competitors like Fetch Robotics?

XYZ Robotics competes in the market by focusing on advanced robotic perception and manipulation, which might differentiate their offerings from competitors such as Fetch Robotics, who may have other specializations in the field of autonomous mobile robotics.