Why deliver a two-pound burrito with a two-ton car?! Energy efficiency comes in different nachos and salsa.

The manufacturing industry stands as a cornerstone of modern society, powering economies and driving innovation. However, this sector also faces significant challenges, particularly in the realm of energy consumption. Manufacturing processes account for a substantial portion of global energy usage, causing a shift towards sustainable and energy-efficient practices. In this pursuit, robots have emerged as pivotal players, revolutionizing manufacturing not only in terms of productivity but also in pushing modifications in processes and operations that lead to more creative approaches that result in less energy expenditure.

Simply put, if instead of sending a car to deliver your next Door Dash order, the restaurant sends you a drone or a small city robot, the amount of energy consumed and the impact on the environment is automatically lessened. And I, for one, am definitely grateful for fewer traffic jams or bikers swinging across cars to get at one's door.

Harnessing Technology for Sustainable Manufacturing

Today's robots are equipped with sophisticated technologies that enable them to operate with greater precision, accuracy, and efficiency, leading to reduced energy consumption. These advancements have transformed robots from mere mechanical tools into intelligent partners in the quest for sustainability.

Servo Drives: Efficiency at the Heart of Movement

Servo drives, the motors that control the movement of robots, have undergone a remarkable evolution, becoming increasingly efficient and energy-saving. Advanced servo-drive technologies can reduce energy consumption by up to 30%, contributing significantly to overall energy savings in manufacturing operations.

Regenerative Braking: Capturing Energy for Reutilization

These systems harness the energy generated when robots decelerate, converting it back into electricity that can be reused or fed back into the power grid. This energy recapture mechanism not only reduces energy consumption but also contributes to the overall efficiency of the manufacturing process. Naturally, for small delivery robots, the energy is delivered back to the robot itself; however, for much larger robots, typically used in warehouses, the "feed back into the grid" becomes a more compelling argument for legislators and entrepreneurs.

Sensor-Based Optimization: Continuous Monitoring for Energy Efficiency

Embedded sensors within robots continuously monitor energy usage, providing real-time feedback to optimize robot movements and reduce energy waste. These sensors gather data on factors such as motor performance, actuator usage, and environmental conditions, enabling the robot's control systems to make informed decisions that minimize energy consumption.

AI-Powered Energy Management: Intelligent Control for Sustainable Operations

Artificial intelligence (AI) is revolutionizing energy management in manufacturing, particularly in robotics. AI-powered energy management systems can analyze sensor data from robots, production schedules, and environmental conditions to optimize energy consumption in real-time. These systems can dynamically adjust robot operations, reducing energy usage during periods of low activity and maximizing efficiency during peak production times.

Impact of Energy-Efficient Robots on Manufacturing

The adoption of energy-efficient robots is having a transformative impact on the manufacturing industry, driving sustainability and economic benefits:

Reduced Energy Costs

Energy-efficient robots directly contribute to lower energy costs for manufacturers, leading to improved profitability and competitiveness. By reducing energy consumption, manufacturers can lower their operational expenses, enhance their profit margins, and strengthen their financial position.

Carbon Footprint Reduction

As robots become more energy-efficient, they help manufacturers minimize their environmental impact and contribute to broader sustainability goals. By reducing energy consumption, robots lower greenhouse gas emissions, contributing to the fight against climate change and the transition towards a sustainable future.

Enhanced Productivity

Energy-efficient robots often lead to increased productivity, as they can operate continuously with no frequent energy-intensive maintenance. By reducing downtime and ensuring consistent operation, energy-efficient robots optimize production processes and enhance overall productivity.

Examples of Energy-Efficient Robots in Action

Numerous companies are showcasing the potential of energy-efficient robots in manufacturing, driving innovation and sustainability across the sector:

ABB

ABB, a global leader in robotics and automation, has developed a line of energy-efficient robots that utilize advanced servo drives and regenerative braking systems, reducing energy consumption by up to 30% compared to conventional robots.

Yaskawa

Yaskawa, another prominent robotics manufacturer, has incorporated regenerative braking systems into its energy-efficient robots, capturing up to 80% of the energy used during braking. This energy recapture capability significantly reduces energy consumption and contributes to sustainable manufacturing practices.

KUKA

KUKA, a renowned robotics company, has integrated AI-powered energy management systems into its robot controllers. These systems analyze real-time data from robots and production processes, optimizing energy consumption based on production needs and environmental conditions.

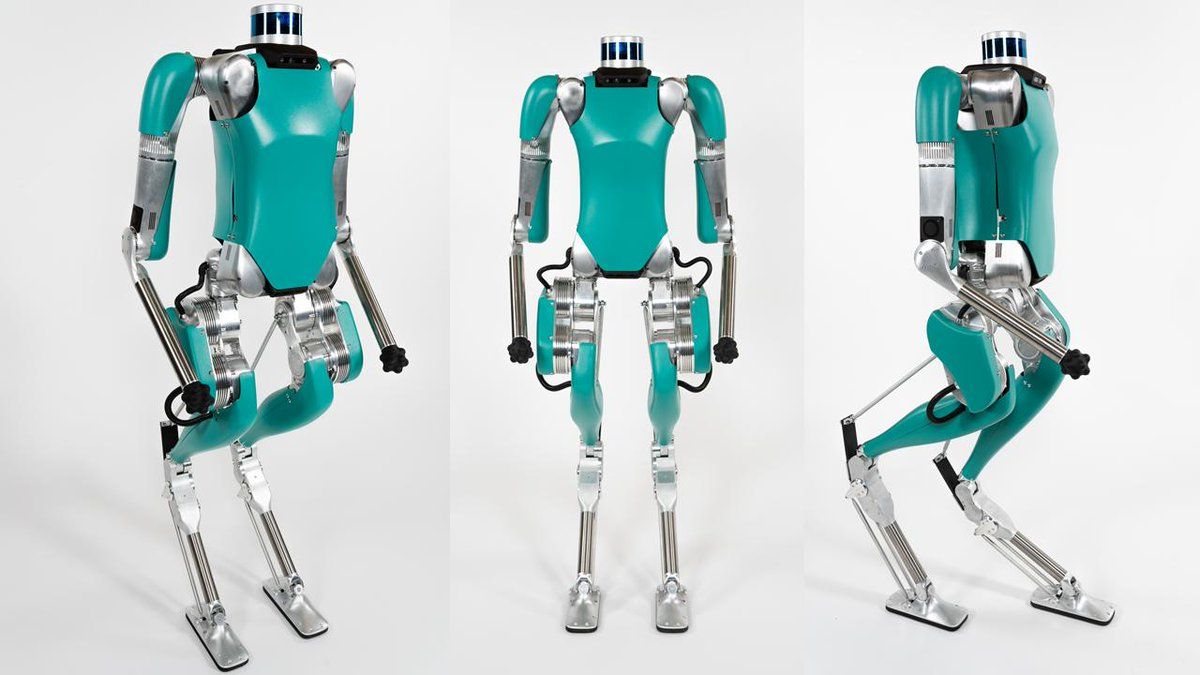

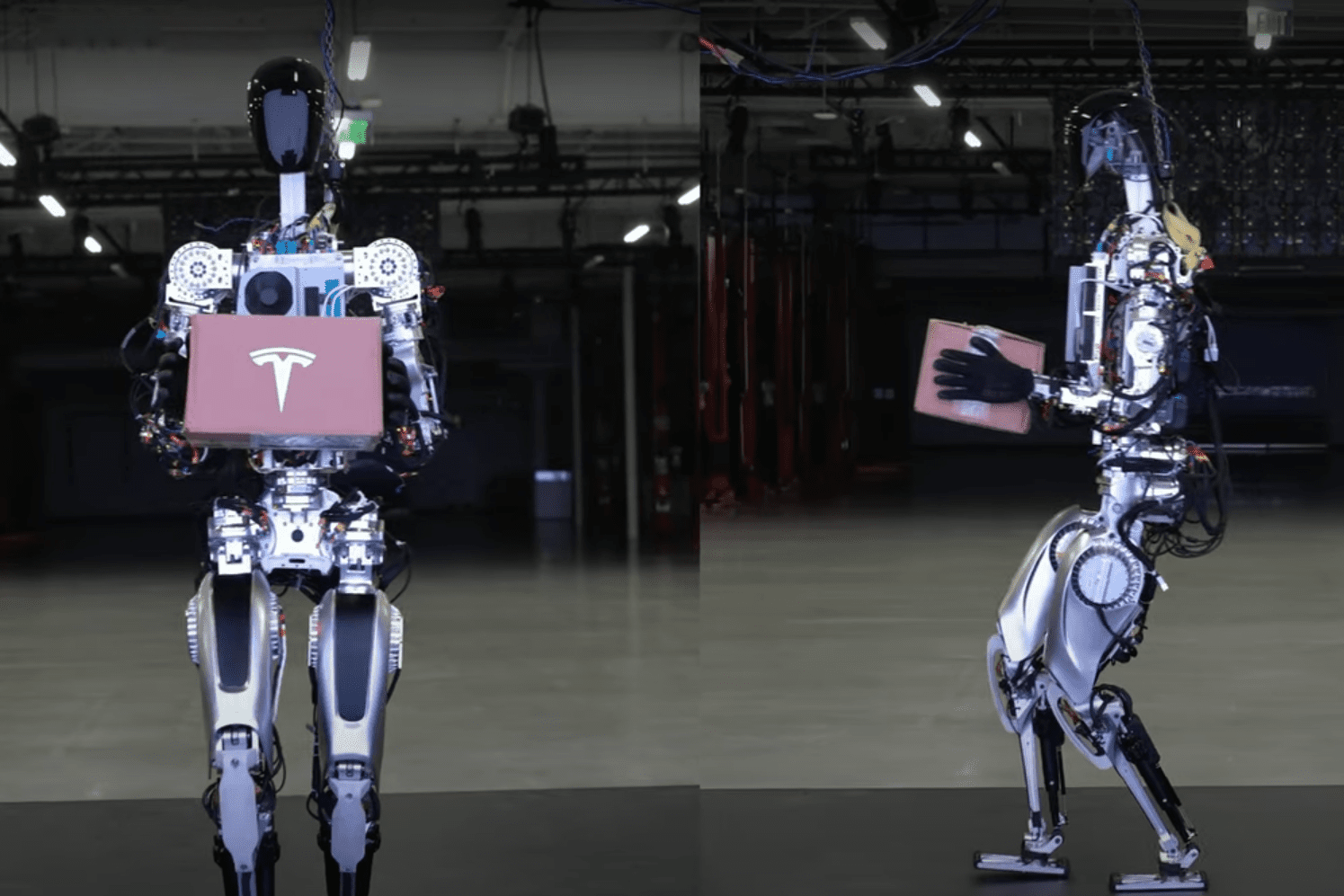

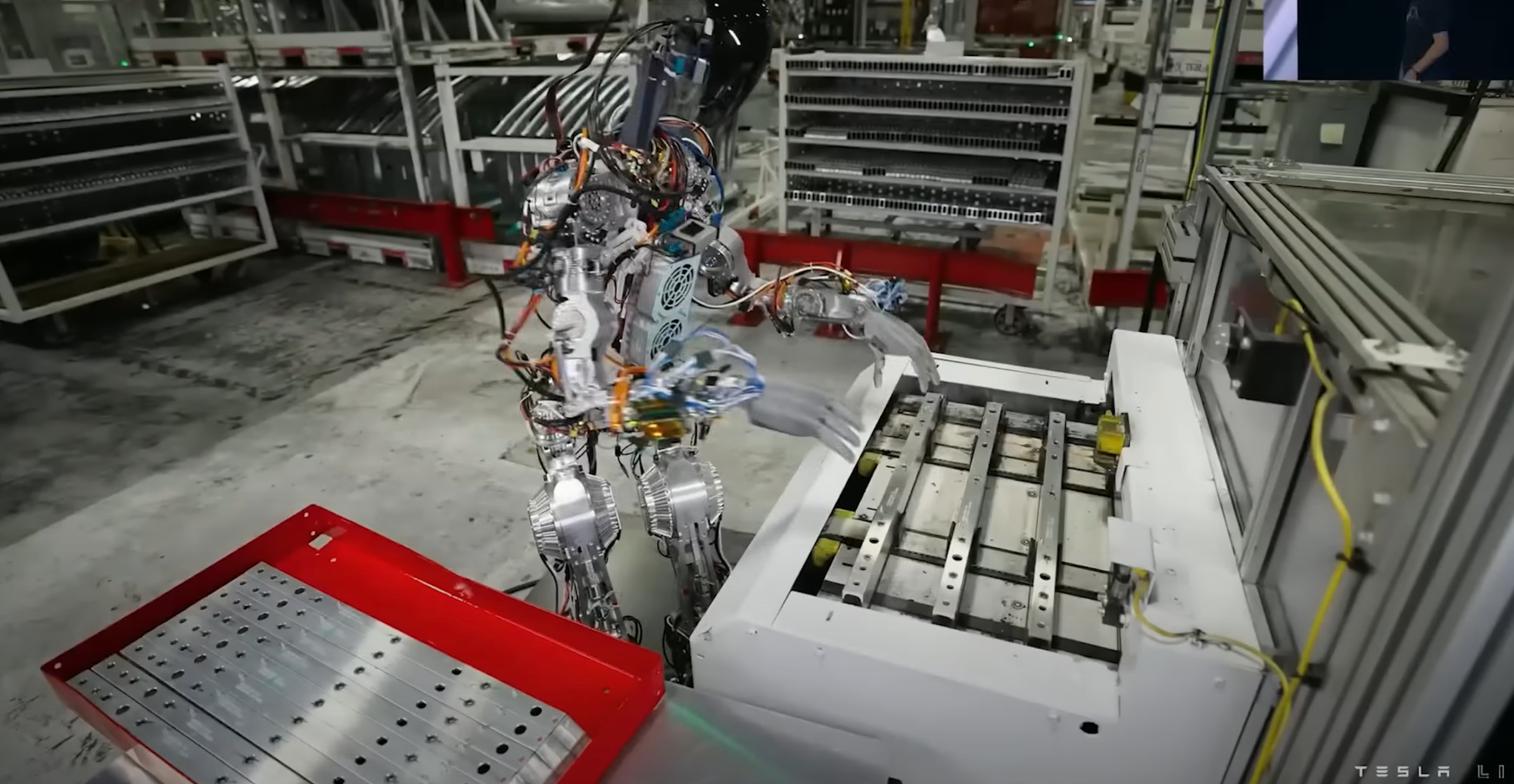

TESLA

And this trend doesn't stop to large equipment robotics but it extends to intense race for replacing or augmenting humans in operations like building cars or supporting older adults. Unsurprisingly Tesla, is making an incredible about of progress in regards of optimizing energy consumption, and their latest humanoid (Gen 2) has reduced weight and consumption by about 30% from Gen 1 in less than 4 months!

A Future Powered by Sustainable Robotics

Robots are revolutionizing manufacturing and delivery of goods, not only by automating tasks and improving productivity but also by playing a pivotal role in achieving energy efficiency. As manufacturing continues to evolve towards sustainability, energy-efficient robots will become even more essential in reducing energy consumption, minimizing the environmental impact of the industry, and paving the way for a more sustainable future.

🤖 That's all I know so far! See you in the next one. [Pink is right]